mechanical testing of very soft polymers|macroscopic mechanical testing : suppliers Low-strength and low-impedance materials pose significant challenges in the design of experiments to determine dynamic stress-strain responses. When these materials are tested with a conventional split Hopkinson pressure bar, the specimen will not deform homogeneously and the tests are not valid. To obtain valid data, the shape of the incident .

Brazil's upper-middle income mixed market economy is rich in natural resources. It has the largest national economy in Latin America, . Ver mais

{plog:ftitle_list}

La tómbola Jujeña es el juego oficial de quiniela de la provinc.

The proposed nonlinear fractal viscoelastic model is used to fit the mechanical test observations of a wide range of soft materials reported by several research groups in the past .The scientific scope of this COLLECTION is dedicated to novel and advanced testing methods establishing a connection to fundamental scientific principles that even show how test results .Manufacturers of soft polymer products, as well as suppliers and processors of polymers, raw materials, and compounds or blends are compelled to use predictive and advanced laboratory . Characterization of synthetic single-crystal composites is shown by cutting-edge electron microscopy techniques that identify the location of the polymeric materials within the inorganic guest crystals, and applications in .

Soft materials may be defined as materials that have low mechanical stiffness and strength and include polymers, foams, and biological tissues. 1 These materials are widely . Low-strength and low-impedance materials pose significant challenges in the design of experiments to determine dynamic stress-strain responses. When these materials are tested with a conventional split Hopkinson pressure bar, the specimen will not deform homogeneously and the tests are not valid. To obtain valid data, the shape of the incident .

Mechanical Properties of Real Polymers We've been talking abstractly for a long time, now, so it would probably be a good idea to talk about which polymers show which kinds of mechanical behavior, that is, which polymers are .Soft multifunctional polymer composites are a class of composite material that can exhibit low elastic modulus (<10MPa) while also have excellent thermal, electrical conduction, and energy storage properties. These functional properties are essential for the composite to be integrated into various devices such as soft thermal, dielectric actuators, tactile and strain sensors.

Differential Thermal Analyzer factories

Based on classic fatigue tests, CeSMA offers a special fatigue test device that is able to test the mechanical fatigue strength of elastomeric and very soft materials.At the same time, the stability of the electrical resistance of electrically conductive elastomers can be investigated depending on the mechanical load cycles, as a resistance measurement through the sample is integrated .

Which is the most used mechanical test? Tensile testing is the most used mechanical engineering test. The fundamental type provides manufacturers with parameters such as stress, strain, yield deformation, and other properties of materials. It is a major metal strength test suitable for polymers, composites, and fabrics.5 Mechanical Properties of Polymers 5.1 Introduction When a polymer is used as a structural material, it is important that it be capable of withstanding applied stresses and resultant strains over its useful service life. Polymers are viscoelastic materials, .The scientific scope of this TOPICAL COLLECTION is dedicated to novel and advanced testing methods establishing a connection to fundamental scientific principles that even show how test results from simple pieces of uncured/cured elastomers or other soft polymers are related to the realistic geometry and loading conditions, and thus, create new opportunities to link laboratory .

At the moment, there are still no standard test methods for the mechanical characterization specifically for additive manufactured polymer components [[53], [37], [54], [58]]. AM technologies and mechanical test standards have to satisfy the requirements of consumers and industries [58]. Also, this paper will summarize a large amount of .

Determination of dynamic tensile response of soft materials has been a challenge because of experimental difficulties. Split Hopkinson tension bar (SHTB) is a commonly used device for the characterization of high-rate tensile behavior of engineering materials. However, when the specimen is soft, it is challenging to design the necessary grips, to measure the . Soft materials are known for their plethora of biomedical applications, intricate structure–property correlation and nonlinear mechanical response. Multiple length–time scale phenomena and hierarchical structure results in their nonlinearity. Phenomenological and continuum mechanical models have been developed to predict their mechanics, which have .Ch.6 Mechanical Behavior of Polymers . STRESS–STRAIN BEHAVIOR . The mechanical properties of polymers are specified with many of the same parameters that are used for metals—that is, modulus of elasticity, and yield and tensile strengths. For many polymeric materials, the simple stress–strain test is

Polymer Labs offered a dynamic mechanical thermal analyzer (DMTA using an axial geometry in the early 1980s. This was soon followed by an instrument from Du Pont. . For most polymer systems, for very precise measurements, one uses a DSC. . This type of testing is not limited to adhesives as many materials see multiple frequencies in the .Common Techniques in Polymer Testing. Polymer testing employs various techniques, each suited for specific properties and applications. One popular method is tensile testing, which measures a polymer’s strength and elongation. This involves stretching a sample until it breaks, providing clear insights into its durability and elasticity. While testing the mechanical or tensile properties of polymer engineering materials for design engineering purposes, testing natural polymers in foods, paper, wood and other materials is important, too.

Mechanical Testing. 4. Strain Hardening of Metals. 5. . The mechanical response of polymers is far more time dependent than that of crystalline materials. Viscoelastic effects (Chapter 15) are much more important in polymers than in metals or ceramics. . Some polymers exhibit very large tensile elongations. Although a few alloys exhibit .

3.3. Mechanical Results of Soft Tissue-Mimicking Polymers. The most significant stress–strain curves obtained after the tests are shown in Figure 12. The mechanical properties (mean ± std), as well as R2 and CV% of the soft tissue-mimicking polymers, are summarized in Table A2 . Pearson’s coefficient values displayed resulted to be close . Materials with elastic moduli in the range of 1 kPa to 1 MPa present challenges for conventional mechanical test methods (Hirotsu, 1991, Miller, 2005, Cao et al., 2005).Nanoindentation methods, however, have be used to characterize the mechanical properties of both soft and hard materials (Loubet et al., 1995, Cheng et al., 2000, Ebenstein .

Large diameter flat punches are preferred for testing very soft materials. Spherical + Can use analytical models (e.g. JKR) + . A hybrid model to determine mechanical properties of soft polymers by nanoindentation The development of a hybrid model – JKR and Hertz- to analyze the elastic modulus of soft polymers . The mechanical behavior for polymers is very sensitive to the deformation rate of the impact test. Thus we are developing and applying several novel measurements that can study the mechanical response of the polymer at different deformation rates and at different material length scales. . elasticity and fracture properties of gels and soft .

Polymer Crystallinity. To account for the physical differences between the different types of polymers, the nature of the aggregate macromolecular structure, or morphology, of each substance must be considered.Because polymer molecules are so large, they generally pack together in a non-uniform fashion, with ordered or crystalline-like regions, called crystallites, .Brittle fracture in glass Brittle fracture in cast iron tensile testpieces. A material is brittle if, when subjected to stress, it fractures with little elastic deformation and without significant plastic deformation.Brittle materials absorb relatively little energy prior to fracture, even those of high strength.Breaking is often accompanied by a sharp snapping sound.

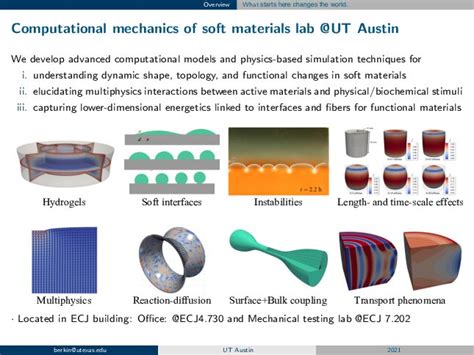

soft material mechanics

Our Polymer Mechanical Testing Services. Our laboratories are equipped to test the mechanical properties of both polymer materials and polymer-based components. With custom-built test fixtures, we can provide critical data about strength, resistance and longevity under a wide range of loads or stress conditions. We work with you to design and . The effect of heat on the mechanical properties of glassy polymers (T. S. Carswell and H. K. Nason, Symposium on Plastics, American Society for Testing Materials, Philadelphia, 1944)Manufacturers of soft polymer products, as well as suppliers and processors of polymers, raw materials, and compounds or blends are compelled to use predictive and advanced laboratory testing in their search for high-performance soft polymer materials for future applications. The collection of 12 publications contained in this edition therefore presents different methods used .usually the first test carried out on an unknown material. All subsequent tests have to be carried out at strains below the critical strain value. TEST GEOMETRIES A variety of test geometries are used in rheological testing. Solids are tested in shear, tension, and bending using rectangular or cylindrical samples. The properties of fluids are .

Carbon Black Content Tester factories

Present and future anatomical models for biomedical applications will need bio-mimicking three-dimensional (3D)-printed tissues. These would enable, for example, the evaluation of the quality-performance of novel devices at an intermediate step between ex-vivo and in-vivo trials. Nowadays, PolyJet technology produces anatomical models with varying .

Tensing testing is probably the most commonly known characterization technique for characterizing mechanical properties of various materials (Scholze et al., 2020), and has been used to characterize soft tissues as well (Innocenti et al., 2017; Cooney et al., 2015; Chow and Zhang, 2011). The method is performed by gripping the ends of the .

polymer mechanical testing

mechanics of soft polymers

Resultado da 1 dia atrás · Rebeldes do Iêmen prometem aumentar agressões na região, inclusive com armas subaquáticas.Uma fragata da Marinha alemã impediu .

mechanical testing of very soft polymers|macroscopic mechanical testing